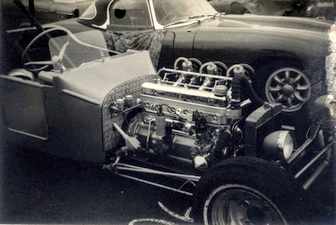

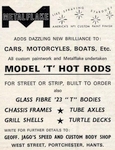

As told exclusively to Geoff designed and built a mould for a Ford Model T body, building a hot rod that he displayed at the 1965 Blackbushe Drag Fest, but it did not run. Advertising in Drag Racing & Hot Rod Magazine, national newspaper coverage and display at the International Racing Car Show helped spread the word. Geoff also got his first hot rod registered for road use. Within years he had sold hundreds of T buckets, many of which became used for drag racing, and Geoff became a full time hot rod builder. Glass fibre just came in at the right time when I was starting to make my Model Ts. I made my own chassis, suspension and tube axle and the first one I built had a straight six Zephyr engine, gearbox and rear axle.

The mould for the Model T body I built from scratch; the bottom piece was actually the roof of a 1930s Singer nine upside down with the windows welded in to get that double curve at the back. I think I narrowed it a bit. All the firewall and around that area was scratch built. I made it about three inches longer on the scuttle at the front to take swinging pedals because much as I like the traditional T with the vertical steering column and the pedals closer as opposed to further forward, they are bastards to drive. They may look good at a show but what I wanted to do was produce something that people could use every day, comfortably, and different sizes of people too, a six-foot bloke would have a lot of problems, he’d look like a grasshopper with his knees under his chin. That’s the reason I made it that much longer. Even then I get criticised by some people who say, oh why didn’t you make it the same as the original? But when I explained they sort of accepted it I suppose. The only reference I had to make the T body was photographs, there were no drawings or anything. What I used to do was find a side view in Hot Rod Magazine and they’d say he’s got fifteen-inch wheels and I'd scale that down and measure that so I know that’s fifteen inches and I'd put it against the body and it didn’t work out too bad as my T body, apart from the deliberate extension at the front, the width and height and all that was only a half inch different from the original, mind you I can’t remember which way round it was, whether it was smaller or bigger, but a half inch out was nothing and I was pleased with that.

In 1965 I trailered my Model T to the Blackbushe International Dragfest, still unfinished, lacking fenders, windscreen and grille. I didn’t expect to do very well, there were a lot more pokier engines there. My whole philosophy was I’ve never been that interested in drag racing and ultimate speed. I wanted to have stuff to go on the street that people could look at, enjoy and cruise with, that was my ambition rather than doing the quarter mile in a couple of seconds. Okay I went up there to drag it but I couldn’t care less if I'd won or not. When I got there, I decided not to run my T. I was worried about the Ford Pop spindles I’d used and didn’t think they were man enough with the big heavy engine. Pop spindles are very fragile and tend to break round the top where the king-pin goes through. Where the grease nipple is there’s not a lot of metal there which is all right for the weight of the vehicle it’s designed for but not for a heavy straight six Zephyr engine. So, I withdrew on those grounds, I didn’t want anything to happen in front of all those people and potential customers. I wasn’t bothered about not running because I was there to show off the product. At this time the Transit had just started to be built which had decent stub axles and spindles which I used from then onwards.

After Blackbushe I rebuilt the front suspension making it stronger. The first setup used coilover shocks on a drop tube axle which was 1½ inch diameter and ¼ inch wall thickness. The second one was 1¾ inch tube and 5/16 inch wall and was a straight tube axle. I used Morris Minor torsion bars under the axle and it really handled well but I didn’t think it was authentic looking but then what hot rod is, it’s what the builder wants but I'd rather have the transverse spring on it. There was a spring manufacturer in Portsmouth and he made them for me after that, he made them in such a way that according to the weight of the engine you could remove or add spring leaves so you got your spring just about how you wanted it which was useful and it looked authentic as well. All the T chassis were quite simple, just a couple of box section inch and a half by three main rails with a kickup at the back for the suspension and the front had the spring perch. We must have made hundreds of T bodies, I know we got through several moulds because when you keep making them out of the same mould the mould gets a bit tired, they chip and bits come off the gel coat inside and of course the body would then have a lump on it. You could make about 200 bodies from the same mould. It’s a job to tell how many T bodies we did, I never had a record, there must have been a record in the invoice book of what we sold but then I sold them in so many ways. I'd sell a T body on its own, I sold one to a guy for a dragster, just a T body and a turtle deck, we sold many to other people who made their own chassis.

One of my very first genuine customers was a chap called Charlie Otwell, I let him drive my Model T at his wedding. He asked me to build him two complete Hot Rods over the years. He lives in the USA now and we still keep in touch today.

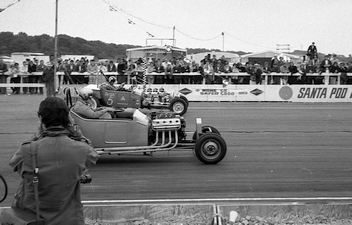

People building hot rods used to buy a lot of our bits and pieces, windscreens as well, that was another thing I had to build and I had to build a machine to make it because the windshield frames were ¾ inch tube with a slot for the glass to sit in. So where do you buy a ¾ inch tube with a slot? You don’t. The first one I made was milled out but that’s such a long and expensive process, so I built a machine which basically was about five or six feet of rail with railway wheels on it so that the trolly ran up and down the wheels, and on that I mounted a seven-inch grinder and clamps along the side. So, what happened was you had a motor and a grinder on about five or six feet of rail going up and down and at the side you clamped your tube down and you just pushed it along and it would grind a slot out the tube all the way down to the end, made a hell of a bloody noise, sparks and crap flying all over the place, a health and safety bloke would have had a fit if they were round in those days. It was the only machine that would do that and I must have ground miles of tubing over the years, each windscreen would take up about eight feet of tube, we made them different heights for what people wanted. I even made a reciprocating saw, in those days you couldn’t buy one cheap, it wasn’t like now with Machine Mart that do saws and all sorts of stuff. So, I made this reciprocating saw out of inch and a half hexagon bars, together, you get three of them and they’ll slide. I built this framework with an 18-inch hacksaw blade and a motor with a crank and that’s all it was and it worked. When you think nowadays you can buy band saws and all that stuff relatively cheap. You think why did I spend all that time making these things, well reason was I needed them and you couldn’t get them anywhere else. I think Hot Rodding is obviously an occupation but it’s a way of life really, all Hot Rodders have one thing in common, if it don’t fit, we’ll make it fit. I ran the T at two meetings at Santa Pod in 1966 and five in 1967 running 17 second ETs at 75mph but there again it was to show off rather than win a prize. It would be sitting on the starting line throbbing away with one next to it. If I came last so what, people had seen and looked at it. It was all in metal flake and chrome, the things I wanted to advertise and that was it.

I did a custom paint job on Brian Holmes’ Mini pickup. He was the chief starter at Santa Pod in the mid-sixties. I sprayed it bronze and dessert sand Metalflake, probably didn’t charge him enough for it but again I was trying to advertise my services and he always had the Mini pickup parked near the start line for all to see.

In 1967 I got my Model T registered for the street with the reg KHO 99E. The first time we took it for a drive, me and the girlfriend at the time took it out, driving from Portchester and did a tour of Portsmouth. We used to park up at Beecher’s Ice Cream place in Guildhall Square. We got stopped five times, in as many miles almost, by the police. I must say they were all young guys about our age and they didn’t stop us to be nasty about it, they stopped us because they were fascinated by the car, they were just like us, forgot they were police men and became Hot Rodders for the few minutes while they were there looking over it. Except for one I might add... I was driving along and this motorcycle cop came up, waved me to stop, which I did and he said what the bloody hell is this? It's totally illegal he goes. I said hang on a minute mate, it’s past it’s test, it’s got everything right, not illegal at all. He was really snotty about it, he said I can’t have that, I'm going to book you, look at the mudguards on the front, I said what’s wrong with them? They’re narrower than the tyre, I said hang on a minute they’re as wide as the tread and the tread is the only bit that touches the road. Then he said look at the bloody exhaust pipe, I could put my hand on that and burn it. I said you’d be a twat if you did, and I looked at his motorbike and said we’ll both have to stop driving because I can see the exhaust pipes and I might put my hand on them. Then he said I can see the fan going round and all the belts, and I said yes but they’re covered with a steel mesh, and he said I could put my finger through that. I said if you do all these things, you shouldn’t be employed by the police. It’s not the last you’re going to hear about this he said I'm going to book you and he took all my documentation and disappeared up the road and I never heard another word from him. I got stopped once or twice after that but in the local area they soon got to know me.

(Geoff’s cat comes in) Hello Hickory Tom, he’ll want his dinner soon I expect. He normally has it at 3 o’clock, I don’t know how he knows the time, he must have a wrist watch or something... Early in 1967 I was invited to display my T at the International Racing Car Show in Olympia along with a selection of dragsters and drag bikes. I took my mum and dad along to see this as they had always encouraged me with my business. I’ll always remember the pride on my dad’s face as he said ‘You’ve made it son’

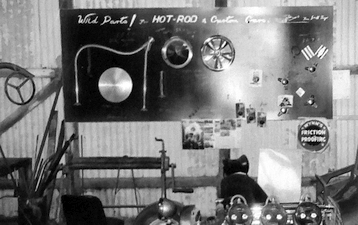

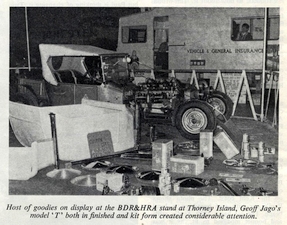

Later that year the RAF Thorney Island Motor Club held their annual Motor Show. My T and the Commuter dragster were invited along with Richard Park’s display of Custom Goodies. Even the local Fuzz were there showing off their new Norton patrol bike and Lotus Cortina patrol car. The business really took off. My T was in magazines getting a lot of coverage and publicity and I had more blokes working for me. Things were going well so I decided to stop working on ordinary cars and work full time on rods. Then I thought, well how about the Model Bs... Gallery: click on any thumbnail for a large image.

Back to pioneers index Back to News page |