As told to Tuesday 5th December 2017 Wednesday 20th September: I made a decision yesterday and ran it by most of the crew; we are going to take the Twin Turbo Cortina to the MSA National Finals at Santa Pod Raceway. This was unplanned, but with the weather looking good, unlike the past few weekends, this is the last chance saloon. If I don’t do this we will most likely not get the opportunity until the FIA Main Event in 2018, which is the best part of 9 months away! It does mean sacrificing running in Super Gas, and also crippling my chances of finishing runner up in Super Street Nationally, and the SPRC Super Street track championship. But a lot of work has gone into the Cortina, and being so tantalisingly close to a seven second timeslip, we deserve it to ourselves to give it a shot. It would finish the season where we want to be. With all things right and give the Cortina a chance to show us what’s in her with the same super unleaded tune she had when we got her. So we will give it a shot, everyone is on board, even Bill and Luke Felstead. If Bill had said no he couldn’t make it, I would have canned the idea. So now I have the task of getting everything up to MSA spec, as we must pass scrutineering to be able to run. The Cortina has not been seen in National Event competition since it has been refurbished by us, so it will draw the attention of the officials. I always go on the principle that if the racecar looks fit for purpose, then the officials will hopefully get the same impression. Not that there is anything wrong with her, but you just want to make sure that you have not missed anything, before you get tech’d in. There is a piece of panelwork that I want to take care of, just boxing in the Accusump so as it is not in the drivers compartment. There is also the job of replacing the brake pipe that we shortened last weekend. Firstly I continued fabricating the boxing in that Bill started and we never fitted for the Accusump. The pipework will also have to be extended and run under the floor as well. Once that was finished and trial fitted, it was then painted. Luckily I still had some paint left. Then it was a case of going and getting the braided hose to make the brake pipe, plus some P-clips. Anthony Mitchell at Burtons Power Products took care of all of that. Then a quick trip to Customville to see Steve Dodds and pick up a couple of Wix competition oil filters. Bill suggested it's about time for an oil change, not that it's dirty but it's just good housekeeping, and I agreed completely. I run the motor on Millers Full Competition synthetic 10w-60, I still had plenty of that so no drama there.

With work getting in the way on Thursday, we will load everything up and go to the track early Friday. All the work will have to be carried out there, but that should hopefully be no major problem. With the Cortina still loaded up from last weekend, it's going to be quicker to take everything there, get pitted in and then deal with it all, rather than unload, disassemble, carry out the work and reload. So we will take the Cortina and get her scrutineered as soon as is physically possible just in case they don’t like something, it gives us time to fix it and get her passed. Worse way, we will get her scrutineered first thing Saturday morning in our allocated time slot of usually 7.15am. Friday 22nd – Sunday 24th September: National Finals, Santa Pod Raceway: You can test all you like at Test Days, RWYB, Fast Ford, Ford Fest, etc. But if you want a decent track, you have to go to a National Event. It also puts you under the spotlight and the scrutiny of all your peers and the more professional side of drag racing. In a nutshell, you better have your sh*t together or you're gonna look real stupid, real fast! Aaron Springford (son of DRE proprietor Gary Springford) and I set off with the rig, and all the tools and parts and pieces you need to operate a team, to Santa Pod nice and early, only to sit on the M1 stationary for 3 hours due to the Air Ambulance landing. Then, upon arrival at Santa Pod, we sat an additional hour due to our tickets and credentials being mislaid. Arriving in the pits late also meant more time used up finding a pitspace. So we lost four precious hours that we needed to get the last jobs on the Cortina finished. With the jobs all done, by now it was 8.00pm. So we missed scrutineering and had kept the crew up late and ate dinner late, and this was just the first day. The jobs needed to be finished were rerunning an oil line and replacing a fitting, replacing the master on/off with a metal one, fitting a couple of other small parts and repacking the chute. Fitting the wheelie bars, remaking and fitting correctly a brake pipe between the two front brake calipers, cleaning the Cortina in and out. Last but not least, changing the motor oil, cutting the oil filter and inspecting it for any metal material but it was clean. I like to show that our racecars are well cared for, I like to create the right impression. This car had not been scrutineered at Santa Pod for years, plus we had virtually rebuilt the car, so there may have been something that we missed. I would have liked to get it done Friday so as we could take care of any problems and take it back Saturday early, but that was not meant to be.

Early 6.30am start as usual for coffee and a catch up with all the crew. Then 7.00am, the crew taking the Cortina up to scrutineering as I went down and signed on as a driver, get my class changed from Super Gas to Super Pro and received my scrutineering slips for both classes. Then straight up to scrutineering, the Cortina went through scrutineering no problem, so back to the pits to prepare for the first qualifier. There was a good gap between the two classes Super Pro and Super Street, about 12 classes for Q1 but then changed as the day went on, so we figured we could get three for sure out of the six scheduled in total. Super Pro is always the second class out, at 9.00am curfew lifts and you can start your engines and 9.30 is startline for Pro Q1 followed by our class Super Pro. I went through the usual startup and drove the Cortina around to warm everything up, transmission, axle, brakes etc. By the time I got back we had already been called, so it was time to get suited up, making sure I had not forgotten anything, then drive down to the staging lanes. As of yet, we do not have an effective way of towing the Cortina easily. So driving down with an already warm motor was okay but I made a note that we would have to keep an eye on that. Being a gasoline turbo motor it builds temperature fast, so you have a smaller operating window before its too hot. Once in the queue, everyone does their job and just gets on with their specific task. Now the whole purpose of coming here is to use the opportunity of a good track to go as fast as we can and learn the new convertor and get everyone familiar with the Cortina in National Event race conditions which is a lot more pressure on everyone. Qualifying slots are class specific, you need to be where they want, when they want and you better be ready. This is also where you start ironing out the bugs and finding the weak points. Super Pro is a big class and has a lot of veterans in it with frighteningly quick kit, it is the quickest sportsman class out there, ranging from 6.00 to 8.99 sec ET’s. We got allocated the right lane for our first run. So as usual I sat on the wheelie bar and put on the Funny Car overboots, then the headsock, Hans Device, Helmet, then the 5 layer gloves. Get into the Cortina and the crew strap me in, I am not being lazy, but with all that gear on I cant see much or reach much, other than what I need to reach to operate the car. Fire up late, as I am running Pete Walters in a blown Top Alcohol Dragster and he will be doing a long burnout. I am again mindful of the engine temp, so I startup late and follow him round once he has three point turned to get into the left lane. Pull round, get spotted in the water by the crewchief, wait till Pete backs up and then get the signal to light her up. Burnout is in second gear, not brilliant but okay, the crew open the door and switch on the Accusump and arm the logger and I pull up to the line. Back into first gear, pull into the lights and put the prestage light on, Pete goes in so I press the transbrake button and start to build boost. I bump in with 3 bumps, it seemed like a long light then Ian runs the tree and I ping the TB button, the Cortina instantly hooks right quite strongly and I pedal and fight to keep her off of the wall. I managed to hold her and keep her straight but I am just inches off of the wall, by now I am sawing thru the gears and still on the wood. Finally at about 1000ft she starts getting a bit loose and rattling the tyres and I pedal again and pull her off the wall. Go thru the finishline, pull the chute, scrub the rest of the speed off and get off the track. The top end crew gather my chute up, open the passenger door and drop it all in. With turbo cars that don’t run $5,000.00 turbos, you cannot shut the motor straight off as the turbos could heat seize so you are better off driving back plus the Cortina has no tow bracket, so I drive back. Once back we discuss what the run looked like which incidentally, contained alot of swearing! The crew reckoned I hit the wall but the cowhorns showed no sign, it was close!! We downloaded the Logger, this showed that I was not on full throttle for all the run which we knew. The tighter convertor was allowing the turbos to build more boost on the startline, it was up around 8-9lb, the previous convertor would only build about 4-5lb. Looking at the timing ticket, we ran an 8.50 @ 156 mph, the 60 ft was where we thought it should be, back in the 1.25 range; with the long light the wastegates were properly banging away on the startline, the Cortina was a real animal on the hit. It was difficult to keep straight and was ugly in the rear tyre dept, really hitting them hard. So Bill Felstead of Comanche Racecars added a one flat of preload and out we went in Super Street Q1; Bill also suggested we +went up from 8lb to 8 1/2lb in the rear tyres. All the usual prep then the burnout, again not brilliant but okay. Armed the logger and Accusump, but this time once in prestage, as I transbraked it and started building boost it started to go into some kind of default mode, seemingly cutting the motor. So I did the best I could and pinged it, running out to the 1/8th and clicked it, still running a 9.58 @ 117 mph. No chute on this run, so I drove straight back and debriefed the crew and downloaded the logger. I wanted to investigate the problem, so did everyone else, we needed to cure this as without being able to spool up the turbos properly all the runs would be compromised. Once on the run it appeared to be fine, it only happened when building boost. Phone calls were made to Jon Hollingworth previous owner and my mate and Gary Springford at DRE, plus spoke to Mark Todd from Street Eliminator who also runs twin turbos. We were grateful for the advice but it was still not cured, so in the end I figured maybe I could roll into the throttle maybe just halfway and that would be enough. Well we found a non public access area where it was safe and tried it, I rolled in a little then a little more and more then thought lets try full. So I got it on the wood and it was fine. The problem was simple, with the tighter convertor, the motor spooled up the turbos slower and the throttle position sensor was getting confused if you went WOT (Wide Open Throttle). So if you rolled into the throttle more slowly you were okay. Valuable lesson learned. There was also a bad steering shake as I slowed down in the shutdown area, not as bad as when the steering mounts broke but still noticeable. On close inspection, the rack was moving in the rubbers, so that was stripped and cleaned and reassembled. Bill also wanted to strengthen the mounts so the crew borrowed some metal (read scaff clamp) and fabricated some pieces to triangulate the mounts. Sefton also borrowed a welder from the Pro Mod Voodoo Hemi team, for which we are very grateful. With that all done we were ready. Meanwhile it had cost us a couple of qualifying sessions and there was only one more round of qualifying to go, so the crew got the Cortina reassembled, I got changed again and we hurried down as best we could. This was the session where we could not make both Super Pro and Super Street qualifiers on account of their being just a class between them. We just missed Super Pro but did make Super Street, so right hand lane again. All the usual stuff, I just about had the temperature of the motor where I wanted it. This time I was going to do a two gear burnout after talking to Mark Todd who suggested it as 2nd gear bands are always weaker then top gear in a TH400 Transmission. To do this I had to press the linelock button mounted on the shifter, start the burnout. Then with the other hand shift into 3rd gear, which meant no hands on the steering wheel, strange but true, it sure felt weird. The burnout was much better and I will do that every time from now on, again part of the learning curve. Once again a real animal off of the startline but I was careful to listen for each gearchange as I could not find the shift on the logger trace between 2nd and 3rd on our first Super Pro run, but this time I was sure I had it. Chute out and no major drama we ran an 8.50 @ 156 mph. Downloaded the logger and it showed that the shift between 2nd and 3rd was barely visible. We serviced the Cortina, ate dinner which was Sefton's famous BBQ, then went and watched Mick ‘Chopper’ Howling play in defence with the Bloodwise Bombers Charity football match.

Sunday morning and the usual early start at 7.00am for coffee. I wanted to do two things this morning as I was beginning to suspect that the transmission was slipping in high gear, mainly due to the trace on the logger, and the fact that I was seeing shift lights which are set at 6800 rpm coming on in top gear and the trace only showing 6200 rpm. The data was at odds with what I was seeing whilst driving. So we checked the trans fluid level and we also reset the shifter cable to ensure it was in gear properly. Unlike a Glide, with a TH400 you can actually get a neutral in between gears, so I wanted to make sure it was shifting into 3rd gear absolutely right. The linkage was a little out so that was reset and the fluid level, which you check with the motor running, was fine. First Round in Super Pro, we had John Atkinson in his Mk1 Cortina Estate, John is a good driver and ex Super Pro Champion, but why should I worry, we are going out first round anyway right? In fact Bill asked if it was worth coming back on Sunday as we were only going to see first round (Bill and Luke were commuting not staying) I said no, come back as every pass is important, so they came back. The third class out was Super Pro and, as I expected, John was waiting for me right at the front of the lanes, they are always early. So we paired up, wished one another good luck and be safe, John wanted the left lane which suited us fine, as most of our passes had been in the right. I got on with putting all the gear, HANS, boots, gloves on right away so as not to be too late getting in. During eliminations, there is a set time that they give you to get ready and all the extra gear I wear meant we had to speed up our routine a little to make it. Also you need two crew to get you in and strap you in, which means whilst they attend to you they cannot do their usual jobs. In all the other racecars I drive, once I get in the car I can take care of myself but not in this case. Just like the Pro Mod teams, I need help as I am wearing the same as they do. Meanwhile Sefton and Aaron noticed the wheelie bar bolts were a little loose so, unbeknownst to me, Sefton goes back to the pits gets the tools and fixes it. This is all part of getting to know what the car does and understanding it. We dialled an 8.30, as we had never been that quick yet. I fired up and pulled round, John does a long burnout so once the crewchief spotted me in the water, I sit and wait, I have had my little bit of me time to focus and relax so I am ready. With the signal I start the burnout, hands off steering wheel I shift into 3rd gear, hold the rpm at 4500rpm, get the signal to pull out which I do bring the car to a stop then the crew open the door get some of the smoke out, check tyre temps, Sefton arms the logger and opens the accusump valve and we are ready. Meanwhile, I have already shifted back into first and have checked the gauges and put the fan on as well, as the water temp is already 150 deg. I lit the pre stage and John does the same, he goes in as I start building boost, rolling slowly into the throttle and building up to the 3400rpm launch chip, I watch the boost gauge and it starts creeping up, it reaches about 5 psi so I now start bumping in, three bumps flickers the light, the fourth one puts it on solid. By now the Cortina is banging away on the gates pretty hard, the tree runs and I ping the TB button, pedal a little out to 60 ft as she scrabbles for grip and moves about a lot, then back on the wood and hit the shift dead right on the 1-2 shift, the Cortina is calming down a little and accelerating real hard, the 1-2 shift still comes up before two seconds into the run. I hit third a little early, just to get it done and distinctly hear the motor drop rpm so I know that the transmission is working good. I am catching John, so as I am passing him at about 1200 feet I have eased off the gas and take the stripe. Bill won’t be impressed that I did that, but the racer in you wants to win and instinct takes over. Low and behold, the win light comes on in our lane, I get the chute out, pull round, the top end crew are now familiar with my routine and hand me the chute whilst the Cortina is still running and I drive back. You may recollect that I do this to ensure the turbos don’t heat seize after the run. Back at the pits, we turn the Cortina round and download the data. Prior to that run, I suspected we had hit a brick wall at 8.30 but we ran 8.34 and I had plenty in hand which was encouraging. Next time out was in Super Pro again due to the size of the class. This time, Laura Turboville with a seven second dragster, so with everything healthy I drove down, this round we had a little more time to prepare in the lanes so I made sure I was in and comfortable earlier. Laura broke out in round one, so we had lane choice so I took right; on this run I was going to focus on hitting both shift points bang on, so we dialled an 8.20. I did all the same as before, waited for Laura to back up before starting our burnout, I probably gave it a little more in the burnout as the smoke inside the Cortina was thicker after I stopped. Sefton armed the logger and the Accusump. Into prestage, Laura did the same then staged, I built up the boost all the same as last time, bumped into stage but gave one more bump just to make sure she didn’t flicker the light, the tree ran and once again I had to pedal to straighten her up then straight back on it, this time I was being chased. I hit the shift to second good, and then hit the shift to third good, as I went through the finishline, I saw my win light was on, so Laura must have gone red. It felt quick through the lights, got the chute out and stopped her. Round the corner the top end crew gathered in the chute and put it in the car. I drove back and was met with a lot of grinning, smiling, laughing crew. We ran 8.10 @ 173mph, which was the Cortina's new PB and my fastest ever mph. We turned the Cortina around and downloaded the logger, which now made a lot more sense as I was on the wood the whole run after 60ft, you could clearly see the shift 1-2 and 2-3 so everything was now making sense. With only 12lb boost the 1-2 shift dropped the rpm 1500rpm but on the 2-3 shift the boost is 20lb so the stall speed of the convertor moves higher, which means unless you hit the shift point which is 6800rpm you most probably wont see a big rpm drop on the shift trace. Now I have seen this it makes sense, the other surprise was how just hitting the shift knocked a real chunk off of the ET and built monster speed.

Next was round one of Super Street, where we had qualified last and had 2018 champion elect Leigh Morris first round. I lost a very, very close race to Leigh at the Euros and that was when driving my Chevy Monza, Leigh is a very good driver. So this one would be all on the driver, with no possible way of judging a 10.90 pass in a Cortina that had just gone 8.10. Just to put this into perspective, Leigh was 2018 Track and National Champion but I was currently in second place and in bringing the Cortina I did myself no favours as Dave Cherrett was just 10 points behind me in the National Championship and with him qualifying better than me was now level. So I needed to go a round further. Leigh put me in the right lane which is fine and we did all our usual stuff, arming the Accusump and logger, it was better to keep the routine the same. I launched the Cortina the same as usual but with a little less boost in the manifold off the startline. I paced Leigh, both of us watching the other, and at the stripe or just before he made a dash for it and I did the same, as I went across the line I figured I had not quite caught him, and he took it. But my win light came on and I was ecstatic, I had got around a very good driver. When I saw the ticket my suspicions were right, Leigh took the stripe by .008 but he broke out and I had taken a little off of him on the startline so I did not break out, and won. It's always a close one with Leigh and myself. Back in the pits we turned the Cortina around as quickly as we could, and got ready for the quarter finals in Super Pro. I had the Giles and Hartley Dragster with Dan driving, we decided to push the Cortina down to keep heat out of it. It was difficult to push it felt like a pad was binding so I drove her down. However I could feel that the brakes were getting worse, by the time I stopped in the staging lane, the car was immovable. So reluctantly I had to tell Daniel that he was on his own and after leaving the brakes a while to cool down I then drove the Cortina back to the pits as you still could not push her. Bill set to work and discovered that the rear brake circuit was sticking inside the cylinder, so it was game over. I reported to the Race Director that we were officially broke and told Karen Stevens that she would be running solo in the final of Super Street. Meanwhile Dave Cherrett had lost his first round in Super Street so I was now officially runner up in both National and Track championships. But hey, how could we possibly be disappointed? I was only expecting to go one round in each class, and winning three and leaving undefeated, plus making huge progress with the Cortina, PB in ET and a huge top speed. The round of Super Pro that we missed would potentially have seen us make more progress, as studying the Logger from the 8.10 run showed, that there was a lot left on the table out to 60ft and beyond. This may however prove elusive to start with as the Cortina is an animal off of the startline and most probably needs a four link change to calm her down and make the car more controllable. All in all, there were so many positives, it really was the best way to end the season, we learned so much and left with no major breakage, and the Cortina is still healthy. There is now plenty of time to get everything done in readiness for the 2018 season. Our goal at the beginning of the season was to loose 400lbs in weight off the Cortina which we did. To upgrade the chassis to a 7.50 certificate – done that. To run a 7 second pass, which in all reality was very optimistic, but we very nearly made that as well. Now we are into the off season and there is a whole host of upgrades to be carried out for the 2018 season. Thursday 12th October 2017 Tuesday 4th July: Bill and I worked on the Cortina to remount the steering rack. I had some chrome moly tubing left over that was the correct diameter, 1 ¼” in this case, so we were in business. Bill also bought his big n' nasty tube bender with him. As before, this kind of job needs a lot of planning before you start so when I asked Bill how long this was going to take and he said ‘all day’ I believed him. It was a hot, sunny day and we were at the PMR workshops, so I made sure we had plenty of water in the fridge, it gets hot in the summer in there. As the rack was still mounted and the geometry was right, this really made the job a lot more simple, as we could fabricate all the bracketry and new crossmember without disturbing the rack. The crossmember that the rack sits on is now below the rack; before it was all above. So lots of measuring and workings out on paper, then I drew it all out on card so as to get the shape. As Bill said, with only one piece of tube, it has to be right first time as there is no more tube, so no mistakes. Well, we did get it bent right and then fishmouthed it one side then the other to fit it to where it picked up the main chassis rails. Then I tacked and welded the crossmember into place. The mounts for the rack were again made from card and fabricated from 1/8” flat sheet steel. With these made in card, they were then made into metal and were welded to the crossmember, so the rack was ready to be removed from its existing mounts and refitted to its new home. This took a little time to make it all look right and remove the old mounting brackets. Then, once all was in place, additional bracing was fabricated and mounted so as to triangulate the rack crossmember for extra strength. Whilst Bill was dealing with that, I went over the rear tubs and fabricated some small pieces and seam sealed some of the boot floor to seal it up a little better. To be fair, I didn’t get a lot of smoke inside the Cortina when I performed a burnout but I wanted to sort it. I also adapted an old window net to fit the wheelie bar to help prevent the parachute from getting tangled in the bar which would not be good!! At Classic Ford we used gaffa tape as a temporary form of webbing and it was successful, so I copied the design. I have also been going over the Cortina carefully from a safety point of view, as we have Mark Norton and Steve Reed from the UK Chassis Tech and UK Safety to recertify the Cortina as the next planned track excursion is to be an MSA National Event at SCR over the August Bank Holiday and we are already faster than the 8.50 chassis tag that the Cortina currently has. We need it upgraded to a 7.50 to run legally, so Thursday night we will hopefully achieve that, which is an important milestone for this project. On the torque convertor front, It's Back! JW Performance Transmission have worked their magic and we now have our convertor back ready to be refitted. Many Thanks to Eric Seccaur at JW’s for all his help and advice.

Thursday 6th July: Bill and Luke from Comanche Racecars met at the PMR workshops to welcome Tech Inspector Mark Norton. It’s always nice to see Mark away from the track as it means you have something finished and ready to make the next step. Mark examined and, true to Jon Hollingworth's word, the bar that Bill had fitted under the transmission was all it needed to get a 7.50 chassis tag. Monday 24th July: With July being so busy at Santa Pod with the lifestyle events, there was no real rush to put the Cortina back together, plus both Bill and I were busy at work. Sadly, there are no more North Weald events this year so no chance for some local testing either. Bill and I met at the PMR workshops and spent the whole day destroying the propshaft tunnel, really! To start with, we were only going to replace the front driveshaft hoop so as removing and refitting the trans was a lot easier. But upon closer inspection, it really was easier and quicker to just replace the whole tunnel section. So it all went, which made re-installing the transmission a lot easier. That was after removing the drivers seat, harness and moving all the ECU and wiring, dash etc. Aaron Springford also lent a hand and although very heavy and having to install the transmission through the door, we got it back in and no-one was seriously hurt. All the pipework was connected up to try to stop any leaks, transmissions always manage to make a real big mess, especially when partially full of fluid and very heavy. Then once the convertor spacing was checked and verified, it was bolted up. You want around 2-3/16th clearance according the JW Performance Transmissions. After clean up, it was then time to connect all the electrics up temporarily, fuel her and charge the battery. We double checked everything then ensure that we had put enough fluid in the transmission. The stick said we had, but TH400 Transmissions hold a huge amount of fluid and I suspected there was not enough in it. So we fired up the motor and ran through all the gears, all appeared to be working perfectly, we put her through a heat cycle and shut her off. The only thing that had given up the ghost was the Accusump which no longer held pressure, that will have to be replaced. It doesn’t sound much, but all this made a long 12 hour day.

Thursday 3rd August: With UK Top Sportsman at the Mopar Euronationals last weekend, there was not much time this week as we ran the Chevy Monza at the event as well as organising it. It was a good event with a lot of very fast seven second doorslammers in attendance and we got the event finished as well. Today was just small stuff really, I gave the Cortina a good clean and made sure nothing in the way of small pieces were lost. Also I checked all the electrics worked like water pumps, fans etc. Tuesday 22nd August: Bill and I spent the day fabricating and installing the new removable transmission tunnel. It was the same shape as previously and managed to weld it all in with the minimum of damage to all around it. Plus I painted it when it was finished so that it won't rust. We used some 16 gauge sheet steel and made sure the propshaft loops were of the correct materials as per the rule book. It doesn't sound much, but again it took all day. Unfortunately, this is when I had to break the bad news to Bill regarding not going to SCR, on account of the trailer bearing problem. Bill knows these things sometimes happen, so no problem.

Wednesday 13th September: Bill and I were back on the case. Over the past month, we suffered a major problem with the doorcar trailer which meant that we were unable to take the Cortina to SCR for what maybe was the very last meeting there. Naturally, as we could not get the bearings to repair the trailer, the weather was glorious and it was a great event. I could have cobbled the trailer bearings together but there was a design flaw in its current setup and it needed re-engineering and doing properly. Having spent the whole of Saturday 12th August stranded on the M1 J10 with a dead trailer, I was not about to go through that again. So I took the time and did it right, hopefully that is the end of the matter. After missing that Shakespeare County Open Nationals event, I already had a back-up plan of the Fordfest at Santa Pod Raceway, Saturday and Sunday 16th – 17th September. So Bill and I embarked on another 12 hour day going through the Cortina and prepping it for the weekend. Firstly we had housekeeping to do on the motor. The valvelash needed checking, along with the valve springs for any breakage. The process is a little less than straightforward due to the positioning of the motor, but once the rocker covers are removed, the lash was checked and was fine. No broken springs either, so the motor was buttoned back up. Next was the reassembly of the interior, i.e. refit the drivers seat, also refit all the interior panels properly. We had previously fired the motor to check the transmission was working correctly when reinstalling the convertor. Next, the transmission tunnel and the wiring had to be properly installed. We connected up the shifter wiring and the linelock button and finished assembling the shifter itself. The front also had to be fitted and the bonnet, then the rear wing and the boot assembly. Lastly, the motor was once again fired up, and we reversed the Cortina out of the workshop. It was now that I discovered that there was not a lot of drive in the transmission. I had seen this before with a TH400 and signifies low trans fluid. So I drove back into the workshop and painstakingly filled the trans, ran it again going through the gears and checked again. All in all, I probably got the best part of another gallon in the trans before it registered right. Then it was ready for loading. I also had another go at repairing the driveshaft sensor, hopefully I will be more successful than my first attempt. Then we loaded up everything that we needed for the weekend, part of all the work that needs doing that nobody sees. The trailer was also checked once again for wheel bearings, I do not want a repeat of before. Saturday & Sunday 16th & 17th Sept – Ford Fest: A leisurely trip to Fordfest at Santa Pod, as our tickets did not allow us entry until after 12.00 Saturday. To be fair, after spending nearly the last two weeks at the track at VW Action, then European Finals the late arrival suited me fine. It allowed time for a nice breakfast and a unrushed journey. Arriving on the dot of 12.00, the crew arrived at the same time and we went in and got pitted. The objective of this event was to evaluate the new JW Transmissions torque convertor, make sure everything still worked okay and make some hits Saturday just out to 330ft. As much as anything, to get me back in the saddle with a turbo car and get the crew up to speed with the systems that need switching on and when. Alas, none of this got done as the rain (which was NOT forecast) started as soon as we unloaded the Cortina. It did briefly stop long enough for us to get the wheelie bar on it and for me to drive it around the pits to get some heat in it and ensure everything worked. Also, crewman Sefton Whitlock got time to go over the car and nut and bolt it. It’s always a good idea to get another set of eyes on the car. But that effectively was it, the weather that came in was nothing like what was forecast. To be honest, if that amount of rain had been forecast, I doubt we would have gone. Sunday dawned and once again it rained off and on during the early morning. As usual the whole PMR Crew were all up and drinking coffee at 7.00am in the RV. But with the rain, not much else got done, other than a film crew had latched on to us from Fast & Loud who were filming a Mk3 Capri they had fitted a Coyote SBF crate motor into and were in the same boat as us - bad weather stopped play. As is usual with Fordfest, despite the weather, it still filled up fast, it's a car meet as much as a drag racing day – a lifestyle event. The track crew were working away, trying to dry a very wet track and we were told that they were aiming for a 1.00pm start. The morning ticked by, the Cortina by now had been uncovered and was creating quite a stir, a lot more than the Mk3 Capri with £40,000 having been spent on it!! We fired her up to dry her out a little and gathered a huge crowd, once that was done, shut her off and went about getting her ready for possibly running, tyre pressures set etc. We were told that the time in the programme of 2.30pm would be our first run, so we aimed at that. Not before we had tried to start her again, only to find an uncooperative car. After much head scratching, Darren Scannel, a good friend of mine, suggested that if the voltage was less that 10.5v when cranking the motor, the EFI will not work. I had unfortunately left the water pump running earlier and the lazy battery was the culprit – and me of course! So with a jump off of the spare battery and jump leads, the motor fired no problem. By the time I had driven around a couple of times to get some warmth in everything, it was time to go. So took all the gear, Hans Device, Funny Car boots and gloves, etc. All of this is quite strange, and I have to get used to it all, as you just don’t use all that stuff when I compete at MSA National Events in Super Gas and Super Street. So we drive down the old fireup road with all the rest of the demo cars. We have already been told that due to the water seeping up thru the track we are all running singles in the left lane. I intentionally positioned myself at the back of the queue so that I had plenty of time to get the safety gear on and in the Cortina. I fired the motor and pulled round, pumped the brake for the linelock, started the burnout in second gear as usual but the linelock did not hold, so rolling burnout it is then. Once completed, I tried to brake, no brake, the pedal goes to the floor. So I then drove off down the track and took the first exit and waited for the crew to arrive so that we could push back. I was disappointed, but better it happen there than on a run. Got back and Bill Felstead of Comanche Racecars quickly diagnosed the problem as being a split hose on the driver's side front brake. With the help of Martin Hill, we managed to remake a hose, just in time for the second demo session at 4.30pm. This went better, not enough rpm in the burnout and the Cortina started to turn in the burnout on me. But there was just enough in the tyres heatwise, I came up to the line, Sefton opened the door and switched on the logger and armed the accumulator. I lit the Pre Stage Lights, made a quick check on all the gauges, all looked normal, transbraked it and built up boost and then bumped it in using the bump box. The bump seemed a lot less violent, I got in and lit the full stage beams. The tree ran and she hooked well, pulled second as soon as she settled and pulled third soon after, for the first time I could actually feel and hear the gearchange. At about 770 feet, it started making a big move towards the centreline and I peddled it then back on it. I ran a 8.55 @ 159.60, then pulled the chute, which didn’t feel like it deployed properly so then got back on the brakes as I was running out of real estate fast, just getting it stopped about six feet into the field. The firecrew and I pushed her out and round the corner. Once out of the way, I refired her and drove her back. Luckily the data downloaded from the logger and that was worth its weight in gold, otherwise the weekend would have been wasted as with a run which was loose and was nowhere near the seven second ticket I was looking for, not much would have been learned. But with the logger, preliminary results show that the now tighter convertor meant that off the startline, the Cortina appears to have slowed down with a 1.35 60ft as opposed to a 1.22 best with the loose convertor. This was the tradeoff that I suspected on account of the turbos not being allowed to spool up quite so easily, the motor's rpms being kept lower, which is where the turbos get their speed from. But with a tighter convertor, the mph will be a true reflection of engine speed. I did check the logger and it seems that I did have the motor spooled up and on 4lb in the manifold on the startline prior to the launch, but it felt alot tamer. The drive off on the line also felt more controllable, probably due to the fact that the motor could not now push through the convertor. Whenever you make a big change to a racecar, the crash test dummy (read: driver) has to contend with it. So I am personally always apprehensive as to what's going to happen this time. In this case it was not too bad AFTER the run, it you can call ending up in the field okay! Monday 7th August 2017 Thursday 18th May: It was first day back on the Cortina since North Weald, which had been very successful. Bill and I set to the list of jobs. Firstly weigh and scale the Cortina properly on a flat surface, this meant firing her up and moving her into my workshop that was now empty, since the Miller 4-Link Dragster had been serviced and was loaded into the trailer ready for teaching and then the FIA Main Event. Once in, we set up the four corner scales and put the Cortina on them. The Cortina had previously, prior to the refurbishment and weight loss, had a small tendency to go to the right off the startline, so we worked a little on evening out the weight seen by the back tyres with driver. It didn’t need much, plus we figured there was still just a touch of preload in the top RHS four-link bar. Other than that observation, we left it alone as the effect of 400lb weight loss would need to be seen on the track. As it sits now, it's gone from dead on 50/50 to being about 3-4% nose heavy. This was expected, as the massive radiator and chargecooler, heat exchanger and pumps are still remaining, as it's still a pump gas motor. The mapping of the instant center in relation to the 100% anti-squat line has also changed a lot too. Without changing anything apart from the weight removal, we need to see how it behaves before we make a bar change. The brakes had worked, but the pedal was a little spongy so needed bleeding again, plus the pedal pad needed to be contoured as it hit the transmission tunnel when you really stood on it. The brakes were bled and came up nicely. The pedal now had also more travel once it was contoured. The last job was to add some bracing to the brake cylinder mount as there was a little flex when you really stood on it. So Bill fabricated the support bracket and welded it in. Meanwhile, I mounted and plumbed in the fuel pressure gauge; I had all the parts but just didn’t have time to fit it prior to North Weald. Then I removed the oil filter and cut it open with a special tool to inspect what was in the filter. There were some small pieces of metal, but nothing more than I expected, you always get some material from the valve springs etc. So finding a little was normal, what you don’t want to see is lots of metal, or worse still copper as the only thing copper in a motor is bearing material, and if it's down to copper, it's already done. Lastly, the bodywork at the back where the wheelie bar exits needed tidying as it was done very quickly and needed shape. Bill made an excellent job of that.

Tuesday 30th May: We just got back from the FIA Main Event last night, where we ran the Monza and dragster with Tony Morris, Martin Curbishley, Mick Howling and myself driving in Super Gas, Super Comp, Super Pro and Super Street respectively. I delivered the chrome moly wheelie bar that I ordered from Andy Robinson Racecars to Bill at Comanche Racecars in Kent, so that Bill could get some more of the parts done, ready for Thursday when we would build the bars on the Cortina. Thursday 1st June: Bill arrived early at around 8.00am and we got cracking on the bars. Bill had already got the bends done, so it was more a case of making it all fit to the Cortina. There is a lot to take into account when building and fitting wheelie bars. There most certainly is not a one size fits all, it really depends what you need the bars to do. This might sound simplistic but it's not. This is what we needed: being a twin turbo car with weight, I wanted the bars to control the launch without upsetting the rear of the car and cause it to unload the rear tyres. To do this it needs to be enough to control, but not hit too hard. The adjustment is never a lot, so you need to be in the ballpark to start with. The second requirement is kinda future proofing the deal, as with all turbo cars, the power is at its strongest at the top of a gear. As we have all seen on the internet, they have a tendency to climb. So to ensure it don’t climb too high, you need a long wheelie bar. As a rule you want the bar 90% of the wheelbase, our wheelbase is 105 inches which means we need a 90+ inch wheelie bar. Bill wanted it to be a mono, so there is less chance of it steering the car. There were also all the mount points and bracketry on the nine inch axle casing that had to be fabricated and welded in place. None of this could be done until the wheelie bars were made, because once made we then had to work out where it would fit so that we got the bar height right. The previous bars we used were too short, the bar height was six inches, but with the new mono bar being 30 inches longer, the wheel had to be nine inches high to allow the same squat on the rear of the Cortina. So there are a lot of parameters to take into account, which is why it took Bill and I 15 hours to get it right, so note to self, wheelie bars take three days to fabricate and mount, not two! It's not the first time Bill and I have put in a 15 hour day on the Cortina, it won't be the last, but if we wanted to be at Classic Ford for the Face Off competition which is heads up Ford cars only, we needed to finish the wheelie bar off. So at 10.30pm it was finished and now we could prepare for Classic Ford at Santa Pod.

Friday 2nd June: I spent the day making sure all was good with the Cortina, I changed the engine oil, using Millers 10w60 fully synthetic, charged the battery, packed up the race fuel, all the tools and trackside equipment that you take to operate at the track. Believe me you need a lot of stuff. Then I got the trailer and loaded the Cortina, doing it all on my own, I only got drowned by heavy thundershowers twice and the Cortina got drowned once. I had everything finished by the evening, ready to go. Saturday 3rd June: Classic Ford at Santa Pod Raceway is actually on Sunday but you need to get in early and prepare to avoid doing the headless chicken on the day. Classic Ford is a very busy event, so experience has taught me to get there early as I don’t do headless chicken. Plus all the small jobs like fitting the wheelie bars and setting up their height, doing a nut and bolt check and any other jobs, giving the Cortina a quick clean etc, had to be done. This was our first time at the track with this car since we rebuilt it so a hit or two Saturday will give us valuable information for Sunday's race. We arrived a little before 12.00 noon Saturday, got in and pitted. Then we unloaded the Cortina and started preparing, as we do all our cars. We checked the tyre pressures, put the battery on charge, and fired up the gennie (no plug in power, its not a national event). Whilst the crew got on with that, I went and saw one of the organisers to find out when we were running on Sunday, then went and had a look at the track. The RWYB was reasonably busy so I walked the startline to see what grip was available. With mainly street cars, their wheelspin starts with a harder rubber compound tends to take the glue off the startline. Being a warm day it wasn't terrible, it is what it is at RWYB. I signed on for the RWYB and went and found Bill and Luke from Comanche who actually had four of their customers and former customers testing that day. The main one was Ray Tucker whose beautiful Twin Turbo Corvette was debuting as well as our Cortina. Ray's Corvette is exquisite and very trick, it’s the culmination of about four years work and is a £100,000+ piece. Back at the pits, we fitted the wheelie bar and then checked the height. There is a fair bit of bend and play in a nine foot bar, so I pre-loaded the rose joints to make it stiffer and lowered it as well to get nine inches of clearance. I fired up the motor and took the Cortina for a little drive, to ensure we had bled the brakes okay and also that the adjustment to the shifter worked, which it did. Lastly, as I had oil changed the motor, I wanted to get it warmed up and ready for a pass and then check the oil level again. With all that done, we topped off the fuel and set the tyres. Off for our first run for Saturday, the RWYB was pretty busy so there was an hour wait in the queue. I got down there, pulled over and went through the process of putting on the funny car boots, HANS device, head sock, helmet and five layer gloves. I climbed in and got strapped in by the crew chief and Joe. I got the signal to fire up, got some heat into her, it’s a pretty hot day anyways. I pulled round, got spotted in the water, linelocked her and into second gear for the burnout. The line lock didn’t hold too well, which is usual for most cars on their first pass of the day with cold brakes. I came up to the line, Joe armed the logger, not too much smoke in the car, clicked on the pre stage light. I hit the transbrake button after taking just a second or two to make sure all the gauges were showing what I wanted. I rolled into the throttle to build boost, bumped in lit the stage lights and pinged it when they ran the tree. She hooked pretty okay but I could feel and hear she was struggling for grip, had to hit the shift into second real quick and steer all at the same time, was on and off the throttle to get her down the track. I returned to the pits with no drama, but the track just wasn’t there for this kind of horsepower. We ran a 9.2 at 132mph. So we downloaded the data once we remembered how to do it again! I elected not to run her again Saturday, there was nothing to learn, not enough bite for 1500hp with all the street cars pounding on it. I decided to wait until Sunday and some more track prep. Upon checking the data, I found no oil pressure or fuel Pressure trace, so we tracked down the wiring to find that a switched 12V power wire simply needed reconnecting to the two sensors. Sunday dawned, we were on the Cortina at 8.00am, but I fed and watered the crew with McDonalds first, and then went through some usual prep work, tyres, etc. I elected not to go through the valve lash, as with only one pass on the motor, there was no reason to do it. So I cycled down to the startline to see what work was being done, signed on and checked the schedule again so I knew when we were running. Our qualifying slots were 10.00am call for 10.15 startline and 2.00pm call for 2.15 startline, with the Final for the two fastest at 4.00pm. So we needed to get everything ready for the 10.00am call. Being that we had been racing the previous weekend at the FIA Main Event, everything went real smooth. Although this is a new car to us all, the morning routine is well practised. There were some nice pieces there, the Mean as Hell Ford Sierra ex Pro Mod car, plus a few more 9 and 8 second cars. When the call came we were told to drive up to scrutineering then back down the old fire up road to the startline on account of the rwyb lanes being full. I knew that would be the case but being a hot day again it put plenty of heat into the motor. We parked up and got ready, I elected to hang back a little to see what the competition would run. There was the usual prep process of me being dressed by the crew then helped me in - unless you do that you would bash the crap out of your crash helmet on the cage every time you get in. We ended up left lane which I figured would be a bit of a problem on account of where I fitted the rev counter with regard to seeing the tree. Guess what, I was 100% right, so once pre staged I had to bend double to see the tree as I bumped in. Got staged and pinged it, she hooked a lot better and I got in a reasonable pass but not perfect and I had to pedal a little and was late on the 1-2 shift, but I was still about two pages behind the car at this stage. There really is no substitute for seat time and this was after all, our first ever full pass. So I am feeling the car for vibration, trying to keep her in the groove, hitting shift points and listening as well as keeping good spatial awareness, where I am and where the other car is. Once I got into the shutdown area that’s where the fun started, I was probably around 150mph plus so I braked quite hard which worked out well, the brakes were doing their job, but as is not unusual the oil pressure in the motor started to disappear rapidly, so I lifted and feathered a little but by that time the oil pressure disappeared completely so I switched the motor off. Just as I did that the oil pressure came back, then I realised that I was running out of real estate fast. I was too slow to use the chute so I stopped in a straight line and just missed the last exit. The fire crew had to push me back to clear the track which only took a min or two. I got the gear off, HANS etc, then restarted the motor which fired up no problem, got oil pressure straight away although it was a little low. In simple terms, a turbo motor heats up the oil so quickly that it's normal to have lower oil pressure but as a driver it’s not what you wanna see. I thanked the fire crew and drove back, with two notes to self, first use the chute next pass and arm the oil accumulator before the pass.

We ran an 8.48 at 158mph so we had qualified No1 for now. We then had four hours before the next session so we turned the car around as usual, fuelled her and charged the battery, I also removed the air filters and checked the turbo bearings, as they can heat seize if you click it hot, which is what I had done. All was good so all reassembled and we downloaded the data, which now had fuel and oil traces, it also showed that although the oil pressure gauge showed zero when I clicked it, there was still some oil pressure, the gauge actually reads under what we actually have –I have no problem with that! So the chute was unpacked again and checked again as we were certainly going to be using it on the next pass. Its good practise to air the chute every once on a while and get the crew used to it, but it’s always the driver's job to pack it. Its your ass in it, no excuses. Also to prevent the chute becoming tangled up on the wheelie bar we made a simple latticework on the bars with racer tape to prevent this. Then I checked the function of the chute pull lever, so that I knew how far I needed to move the lever to deploy the chute as we were going to need it. The Cortina was very well received by the public and most of the crew were at stages engaged with people on technical matters. For some time now, a lot of Fast Fords have been turbocharged. We got called at 2.00pm and made our way to the startline down the old fireup road. Upon arrival, Santa Pod startline crew Ian Marshall and Dave Warren closed the track and did some quick housekeeping and sprayed the track for us, which gave me time to get in, settled and focused. I got the signal to fired up, I had gone down early this time to get the right hand lane, no more staring around the rev counter! The burnout was good, Joe armed the logger and accumulator, the crewchief bought me up to the line, I bumped in on boost and pinged it. Grabbed second gear real fast, and then with a tiny pedal to settle her on the 2-3 shift I kept it on the wood. Just hitting the limiter in top gear at about 11-1200ft, drove into the chute and then let the chute do the work and made sure I took a wide arc as I came off the track to ensure the chute drogue didn’t get caught up on anything. Well that was a full pass, or as near as was possible on the day. I kept her running, but with no-one to put the chute in the car, I had to switch off and get the chute myself. Once retrieved I restarted her and drove back to the pits. I was a little surprised to see we had only run a 8.32 at 168mph, but it is what it is, so we downloaded the data, checked the motor and turned her around. The next run was the final and we were running against Ian Walley who has a wicked MkII Cortina with a 102MM Single Turbo SBF, Ian usually runs at York so I hadn’t seen the car for a while. It was a race against the weather as a storm front was approaching fast. Ian was having trouble getting temp out of his transmission, so I waited for him, when he was ready we went down. This time down the usual pairing lanes as the rwyb was emptying out. I chose right lane and my plan was to run her to 1000ft and then just maintain rpm, I didn’t want to hit the high side chip again. Both cars fired up fine and did their burnouts, Ian staged immediately so I followed in as soon as I could, I knew his trans was cooking. Pinged it we left together and never saw him past 60ft, took it to 1000ft and clicked it, running 8.50 at 154mph, got the win light, job done. Then it rained and we all got drowned loading the Cortina and eventually left with the winning Cortina that had done everything we asked of her, apart from run a seven but with the data from our runs and from Jons old data, I felt sure I could pinpoint what needed to be worked on. Monday 5th June: I had a chance to really analyse the data from our passes and from previous owner Jon Hollingworth’s old data. Well, the story it told was what I kind of suspected. As our 60ft time on the 8.32 run was 1.22, this was at least 2/10th up on Jons 60 ft on his best ET 8.60 and by the time we got to 330ft we made up a little more but from there on we were no faster, plus our mph was lower than Jon's terminals of 172-173. Add to that the fact that we had a taller tyre and our theoretical top speed on the chip was now 208mph, not the 168mph that we got on the chip going through the finish line. When I compared the driveshaft speed to the motor RPM it became clear that even before with Jon, it had recorded an engine speed of 7200 rpm and a driveshaft speed of 5000 rpm. This shows massive slip. If you followed the trace to the finish line, the motor speed just got to 7350rpm and the driveshaft kind of caught up a bit with 6150rpm but never got close. When I looked at our traces, I couldn’t even find an rpm change when I shifted from 2nd to 3rd, in fact the rpm drop from 1st to 2nd was only 300rpm and should have been at least 1000rpm. The only chance we had to improve was on the hit as the launch control only has 5lb of boost in the manifold, as soon as the boost ramps up it just blows straight thru the convertor, which explains why it has not seen a drastic reduction in ET. When I spoke to Jon, he confirmed that the loose convertor was to help the block tread tyres grip on the gearchange as it had a habit of knocking the tyres loose. I then spoke to Eric Secaur at JW Performance Transmission who said with a turbo convertor they look for no more than 3-4% slip, not the 33% we were experiencing. So Bill and I will pull the transmission and get the part number off of the JW built convertor, so that Eric can pull the file and let me know if there is enough scope to tighten it up sufficiently.

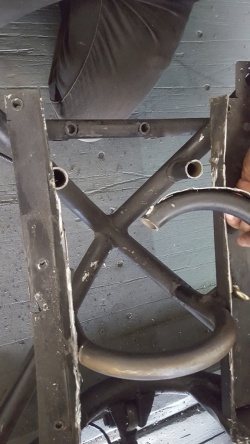

You have to keep your feet on the ground here and not be too optimistic regarding just how fast she will be with a locked down tight convertor. The loose convertor means that the Cortina was never close to fulfilling its potential when Jon owned her, the block treads they had to use in street eliminator to get from point A to B meant you had to use convertor slip so as not to shock the tyres. We now do not have such a restriction, we also have no exhaust back pressure as we can use cowhorns, we also have 400lbs less weight, lastly we have slicks and taller gearing to let it eat. So with a tighter convertor, in a real world scenario we’ll be able to see how much difference it will all make. Remember, the power of the motor is unchanged, it's just how it sees the track and how we can now apply the power, its going to be fun to watch. Tuesday 13th June: Bill and I both worked on the Cortina today, the first job was to remove the transmission, so that I could get the serial numbers off the JW Transmissions torque convertor. With the removable floor, trans tunnel and doors, the job was not a long affair, the only tricky part was the remaining trans tunnel. So we both decided that it had to go, so next week we will make the remaining tunnel removable as well. The transmission is simple, too heavy to now have easier access. It only took an hour to get it out. We then turned our attention to the steering rack mounts. On the last pass, I felt the steering do something weird, the straight position on the steering wheel moved in the shutdown area on the last run. We investigated this and found a mount had moved. We figured, now the Cortina was wheels in the air on the hit, that the shock had somehow cracked one of the welds. The solution was simple, we would mount another small tube crossmember just for the rack and triangulate it for strength. Other jobs were also discussed and planned, an undertray, also cleaning, normal housekeeping maintenance and replacing the black gauges with silver so that they match. Now the Cortina was unloaded and in my workshop, there was plenty of room to work on it.

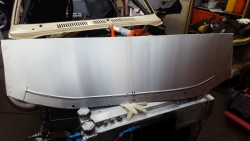

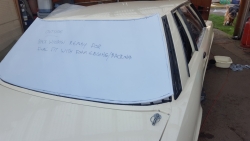

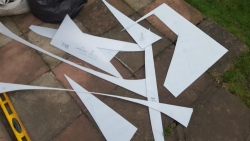

Upon reflection, there were a lot of things that just flat out worked that need to be mentioned, as whenever you build these things, its an educated guess at best. The wheelie Bar worked real well, no complaints so far. Despite being mercenary on what got removed from the Cortina - and there was a lot - there seems to be nothing other that a quarter bumper that came off during a run. None of the panels seemed to move, the doors stayed put, the tops of the doors didn’t get bent out due to the wind at speed. The whole aero package seems to be happy so far, the Cortina definitely felt stable and was not unsettled when the chute deployed, which can be a problem with a lot of cars. The transmission rebuilt by Terry Robbins at Robbins Race Cars seems a-ok. The motor despite our unfamiliarity with it does not appear to have suffered and worked perfectly, doing everything we asked of it. The steering and suspension worked fine, the brakes were good, the driver's position is good, no real complaints. So all in all a lot more positives than negatives at this stage. Saturday 16th June: It was a really hot day today, so a 7.00am start on the Cortina, we cleaned her up after the exploits of Classic Ford, plus removing the transmission. We had already had a courier collect the convertor and it's on its way back to the States for a freshen, and to have the stall tightened up. I removed the black gauges from the dashboard and replaced them with the silver Autometer gauges that Tony Morris brought over for me. Now all the dash matches, a small point but it keeps the look right, so it was just as well that I marked all the wiring on the loom behind the dash so as to make the swap easy. The temperature gauge is electric and I had to disturb a lot of wiring to fit the new ones. I also secured the quick release fittings more firmly, as I had already refitted the oil pressure line wrongly once, which you find out when you fire up and have no oil pressure registering! Luckily there was no mess from the loose pipe but it highlighted a potential problem so I fixed it. Tuesday 26th June: I called Eric, as although it seemed that the courier company may have lost my convertor (which is why I insured it), I got notification whilst at the Summer Nationals driving the Monza in Super Gas and Super Street that it had arrived at JW’s in Florida. After discussing it with John Winters Jnr, Eric and I decided that changing the stator to a P/N 026 stator was the best move as it allows slip low down so it makes spooling up quite easy but locks up tight when up in rpm. For our combo that’s perfect, it’s a little more cost but it will do the job right. It took just 24 hrs to get the convertor upgraded. My courier collected it on Thursday and I had it back with me here in the UK on the following Tuesday. Nice. Wednesday 15th June 2017 Wednesday 5th April: Bill wanted to get the new Dashboard mounting finished today. I had ordered the Dzus plates and springs from Mark at Hauser Racing on Monday and they arrived the next day. So Bill got cracking on that, meanwhile I got stuck into framing the front windscreen ready for the screen to be mounted. The best way I have found is making a wood frame that you use to bring the level that the screen sits on flush with the roof, pillars and scuttle. Because a screen is usually held in by rubber, when using lexan you have to bring the height up so that you don’t get a sunken in screen. This will also aid the aero on the frontal area. But it’s very time consuming and with the shape of the screen you have to bend and shape the wood. I used 15mm x 12mm battening from B&Q, plus you have to use saw cuts to be able to allow the wood to bend into shape. Then you need to bolt it into place and paint the wood. Once in place you then may have to shave it down in places to get the right recess for the lexan to drop into. What I have just described took 6 hours to do so allow time and be patient. And yes this is not the first one I have done, so take your time and buy lots on wood for when it snaps when you’re trying to get the shape. I used stainless countersunk M4 screws and nylocks to fit it all in place. The screens will be the very last job as I don’t want them damaged by welding or cutting. Plus, with no screens, the access to everything is excellent, with the screen fitted jobs like the dashboard would take twice as long. We also looked at remounting the front wings and bonnet assembly, being as the front used to be a flip front so that you could gain access without removing the front and wings (one piece front, but all in steel). I did not need that and much preferred just taking it off when needed. Some of the door gaps etc were bigger than needed and the way the front wings were kicked out behind the wheels needed sorting. In the end, we cut the lower mounts off and remade them, and moved the front wings back a little to close up the door gaps, making sure the door could still open without catching the wing, which had been a problem before. Wednesday 19th April: We lost a week working on the Cortina on account of racing at Easter’s Festival of Power at Santa Pod Raceway. But now were now back on the Cortina, and as usual it took a while to get back into the swing of things. I still wanted to finish off doing the front wing on the passenger side and moved the wing out a little more to line up with the bodyline better. This actually worked, and with that done, we carried on. Bill finished the fitting of the dash last week, but now the end pieces and the underside returns needed making. Luckily the bead roller and the folder came in very handy for making these small pieces - they are perfect. Again, you start by making it with cardboard and once your happy with that you remake in ally.

As you can see from the pics, the steering wheel and extension looks real nice and is very practical when it comes to getting in and out of the car. I decided that I would work on the interior and tackle remounting the panel that the launch control, boost control and data ports are mounted to. This, for now, will go back where it used to be; luckily we did not cut those out just in case. With North Weald now just 3 weeks away, the clock is really ticking. The Data Logger panel went back in really nice and using countersunk bolts the floor piece on that side goes right over it and keeps it nice and neatish! I also then refitted the trans tunnel which is original but powder coated. I had already mounted the new shifter on it and made sure the shifter cable fitted, which it did. This highlighted that we still need to fabricate the mounts for the trans tunnel. I also started working out all the cable runs and routes on the passenger side with the floor panels fitted and secured them. The next job was the steering wheel and where all the controls were going to go. I have a line lock, transbrake and bump box button to install. Before the line lock and the transbrake button were on the shifter, I didn’t want that, plus there is a lot of cable running down the driver’s side of the car. I have seen this before, and is usually because American wiring looms are made for LHD cars so the lion’s share of wiring runs down the passenger side – but the Cortina is RHD. I decided to mount the transbrake and bump button on the steering wheel so that I can control the staging process with both hands on the steering wheel; I just prefer it that way. But I mounted them on an ally plate above the wheel itself so that it’s less likely to hit anything when just holding the steering wheel. The line lock I left mounted in the shifter area. I then spent time picking out the wiring I needed out of the loom and added curly cables so that when I remove the steering wheel to exit the car, there is enough slack on the cable to move the wheel. The last job was remove the steering rack, which was when Bill and I checked the steering and brakes. Bill noticed play in the rack, a quick call to Jon Hollingworth confirmed it had been on the car all the time he owned it, so it was probably due some TLC. Meanwhile, Bill was busy fabricating a front screen support, this stops the screen from flexing and buckling at speed. Again it’s a fairly small piece but it’s a time consuming fabrication. Naturally we used the lightest, thinnest tubing we could find and designed it as a double triangle to give it strength. The last job of the day for me was to reconnect everything back up electronically and fire her up and put her through a heat cycle. It had been at least a month since she had been started and a lot of work had been done. Everything was reconnected and there was enough charge in the battery so we pre oiled her from the Accusump, switched on the ignition and she fired up straight away no problem whatsoever. That was real nice, I can tell you, and it warmed up quicker due to the warmer weather and there were no leaks from anything. A very nice reassuring way to finish the day. Sunday 23rd April: Just to keep it rolling along, I reassembled and refitted the powder coated rear wing today and re attached it to the boot. Again a time consuming fiddly job done! Thursday 27th April: This was the first day back on the Cortina proper, due to the Festival of Power and Paul Marston’s Drag Race School teaching at Santa Pod Raceway which went very successfully. Other than the Monza being on alcohol in cold weather, they do have a tendency to spit back when starting from cold. It did so and broke two ring gear teeth clean off whilst teaching so that had to be fixed as well. Not trying to make excuses but there are only so many hours in a day! Okay, I’m on my own today, elephant in the room time, its dashboard day. First off, I had to finish the assembly of the dash as the driver’s side pieces were made but not fitted. Then I needed to get the dash cut with holes for all the gauges so that it can go with the other small parts that still need colour. It was a time consuming and delicate job, and if I make a mistake and ruin it, a lot of work goes down the toilet. So I measured it twice or three times, was patient and got it done. I sat myself in the Cortina a good few times to make sure I knew where to put them. It was either off to one side or directly in front. Now I had the steering wheel and column in place, I could easily see the gauges when they were in front, and my hands on the steering wheel still don’t obscure the gauges so that’s where they went. I did speak to Bill and he suggested that the bottom of the dash looked unfinished and said that rolling the bottom edge under the picture frame tubing around the transmission would make it look finished. I could see what he meant, so I figured let’s have a go. The trick with metal is to avoid stretching it too much and so as to get the fold I wanted, I went over it three times, folding it a little more each time so that it was not stretched in a direction I didn’t want. I hope that makes sense. Once I had done that, it really made a difference to the look of it and at last I could see it working. Then with lots of measuring and checking, I cut the holes and checked they were the right size, they were - just. It’s always useful to have a gallon of panel wipe to take off the marker lines so as to have a clean surface for powder coating. When all that was finished, I decided to tackle prepping all the other colouring parts, accelerator and brake pedals plus some more covers and pieces etc. With that all done, it was time to work out the button layout, as it needed sorting out. As the steering wheel was now removable, it was final decision time. Any buttons mounted on the steering wheel had to have curly cables with stretchability built in. I decided to go ahead and mount both the transbrake button and the bump box button for staging with the turbos spooled up on the steering wheel. I mounted the line lock on the shifter, as that keeps the wheel a little less cluttered. This meant extending and reducing some wiring, so I cut out anything with a join in it and installed it fresh. I also avoided using spade connectors and preferred soldering and then heat shrinking insulation on all joints to ensure good contact. Again it was a time consuming job, but you only want to do this once. I also had to tidy up and re-run some of the cable paths as there is a lot of cabling on the passenger side, so the tidier you can get it the better for the driver. After this it was simply a case of running all the powder coated pieces down to the powder coaters. Tuesday 2nd May: With the deadline date fast approaching, Bill and I agreed that, weather permitting, the Cortina would make the opening event at North Weald. It’s next Sunday and there’s still a shedload to do. Still no windows in her, no wheels on her, no braking system to speak of, no steering rack, the list goes on and on. Will we make it? Well it’s still the same as it’s ever been, it just needs hours of work put into it, lots of hours. To help this along and give it our best shot, I decided to take the rest of the week off from work. As long as Bill gets his bits done, I figure I will try to get everything else sorted and will need plenty of time to do it. This has been a six month project, so I will do my best to make it happen. I collected all the powder coating, bought it back and installed the gauges, so now its’ starting to take shape. The powder coating really made a difference, it now looks the part. The first job was paint and laquer the roof panel; Bill and I had spent hours on this and trying to work out what to do with it. Gary Springford at DRE came up with a great idea, but there is not yet the time to do it. So, for now, it’s painted as is and will be fitted. The next job was reinstall the parachute lever and chute cable, running it through the boot. The cabling in the boot also needed tidying and the wiring for the water injection had to be reconnected. Luckily the pictures I took when we stripped it all out was a godsend as it gave me a visual record of what went where. Next I needed to fabricate a piece of bar to secure the battery to comply with MSA safety rules. I used a piece of bar from the Cortina’s removed parts bin to recycle it. Gary Springford did a great job with the steering rack, it was actually internally adjustable on the ball and socket joints and just needed a little play adjusting out. Once that was done it was like brand new, I just had to detail it, clean up the mounts etc and reinstall it. On the front, last job was to align all the bonnet pins and make sure that all six were right and held the bonnet nice and snug, also the boot needed the same work, this was quite time consuming but needs to be right. All that took ten hours. Wednesday 3rd May: Today was purely on the dashboard. I wanted to take my time as there was a lot or wiring to pick out from the old dash and understand, some of which was now redundant. Like the high beam, indicators, etc, but the ignition light and the oil lights were still needed, so I had to ensure I knew what everything did before I removed the loom from the old dash and the clocks. So the long process of marking everything as you removed it started. You also have to ensure you know what is earthing through what, so it all works once you have removed it. There were also the two quick releases for the turbo boost gauge and the oil pressure pipes. Removal and marking took about two hours or so. I had spent about an hour previously working out where I could place everything on the new dash so that it was within easy view when sitting in the car. Everyone has their own ideas about this, mine were, I wanted a much bigger low oil pressure light in my eyeline and I still wanted the shift light on the dash, despite the new to install rev counter having its own shift light capacity. This thing accelerates so fast, I figured two shift lights might be worth trying, as it means you can set one a little lower rpm wise so you have a chance of catching it, especially in first gear.

Then came the job of reinstalling everything into the new dash, the three gauges, the ignition light, the mount for the quick release pipes and the oil and shift light pods. All in all about five hours, but I am pleased to say for once it all worked first time. Also it looked real good. I also replaced the rev counter and moved it further up the cage, this helped with the removal and reinstall of the dash and it’s easier for the driver to see it. I did however need to go online and download the wiring diagrams for both rev counters, as the wires were different colours. Autometer’s website is very useful for that. I fired the motor up a couple of times to make sure everything worked, the last time to make sure the rev counter worked which thankfully it did, having previously lived in Gary Springford’s Hulk Shogun. Lastly I reinstalled the last of the coloured panels that I had collected from the powder coaters with the customary black rivets. Thursday 4th May: Bill is in today, it’s the only day he could spare away from Comanche Racecars and we both knew this would be make or break day. I had earlier that morning picked up the four corner scales from Gary at DRE, the plan being that once we finish for the day then we scale it, well that was the plan anyway! Bill had two major jobs to do today and lots of small ones. The first one we tackled was to fit the roof panel. Bill was really happy with how the dashboard looked and that I had got plenty done. Once fitted, it moved one step closer to being a useable car. We removed the bonnet and one piece front for better access to the brakes etc. Bill and I had to tackle the fitting of the transmission tunnel and the remaining removable floor piece that the tunnel was attached to. Once we agreed how it was going to go in and where it attached, Bill got cracking on that. I decided that tackling the windows kept me out of Bill’s way best, so I started on the rear quarters. Like most of these jobs, although I had got the windows to where I thought they were ready to fit, there was still a lot of fine tuning to get the perfect fit. Also Bill finally won the argument and I blacked out all the window frame area. I wanted to keep as much of the bodycolour as possible but Bill said that it would look horrible. After relenting and painting I must admit he was right! I used a real nice soft brush and didn’t spray it, there are simply too many painted surfaces to spray now and the brush finish looks real nice.